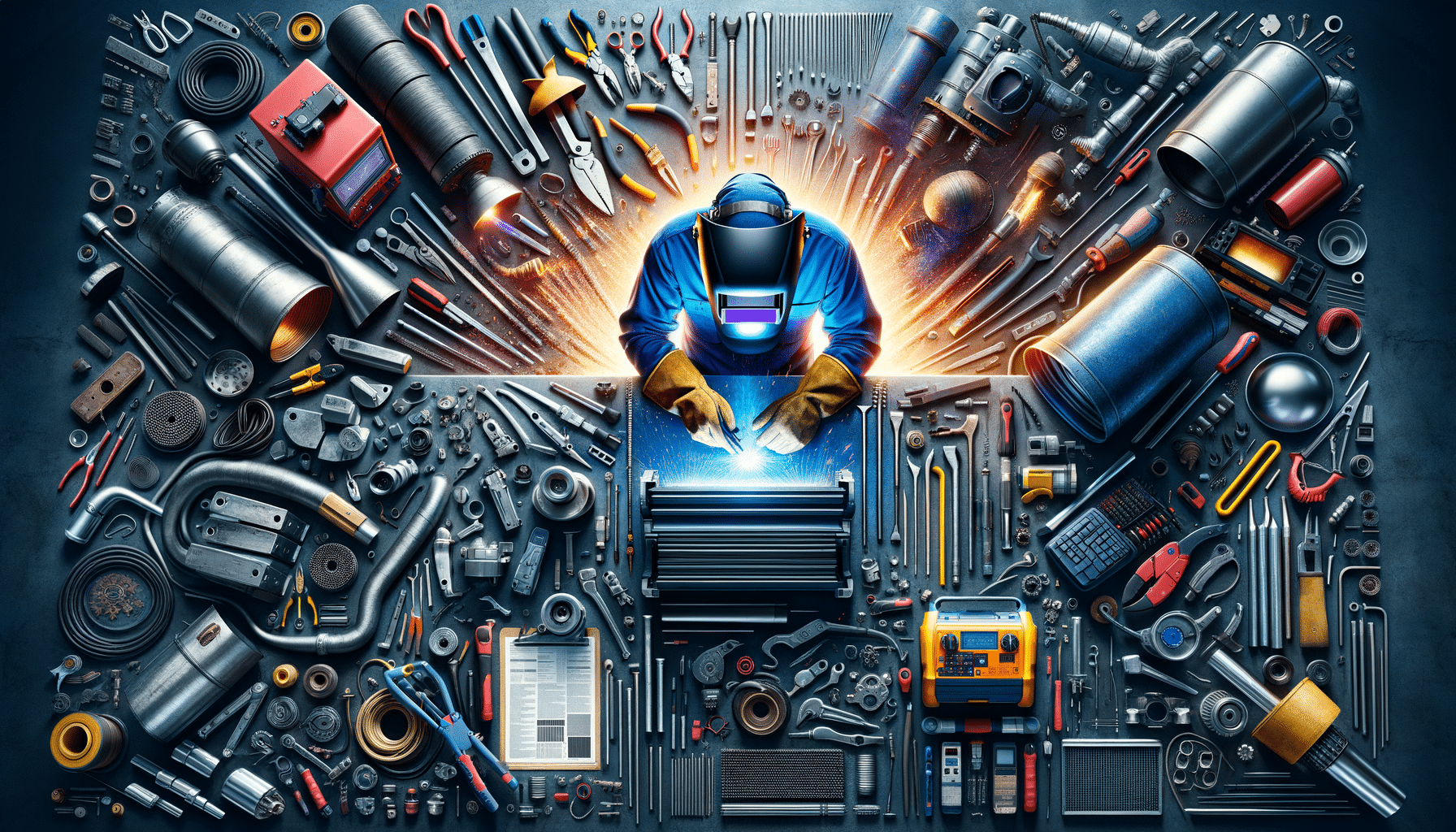

Welding Jobs in the United States: Discover Opportunities in the Welding Sector

The Growing Demand for Welders

In recent years, the demand for skilled welders in the United States has surged, driven by a combination of infrastructure projects, manufacturing needs, and a retiring workforce. Welding is a critical skill in numerous industries, including construction, automotive, and aerospace, making it an essential component of the American economy.

Welding companies across the United States are hiring new workers to meet this growing demand. These positions typically offer a set schedule, clear tasks, and a friendly atmosphere. Many companies are investing in training programs and apprenticeships to attract new talent and ensure that the workforce is equipped with the latest techniques and technologies.

Some key factors contributing to the demand include:

- Infrastructure projects: The need for repairs and new construction of bridges, roads, and buildings.

- Manufacturing growth: Increased production in sectors like automotive and heavy machinery.

- Retirement of experienced welders: A significant portion of the current workforce is nearing retirement age, creating opportunities for new entrants.

As a result, welding jobs are not only plentiful but also offer competitive salaries and benefits, making them an attractive career choice for many.

Types of Welding Jobs Available

The welding industry offers a diverse range of job opportunities, each requiring different skills and expertise. Understanding these options can help job seekers find the right fit for their interests and career goals.

Some common types of welding jobs include:

- Production Welders: These professionals work in manufacturing settings, assembling products or components. They often work on assembly lines and use automated welding machines.

- Maintenance Welders: Responsible for repairing and maintaining equipment, these welders often work in industrial or construction environments.

- Pipeliner Welders: Specializing in welding pipelines for oil, gas, and water, these welders often work in remote locations and require specialized skills.

- Structural Welders: These welders focus on building and repairing structures, such as bridges and buildings, requiring a deep understanding of engineering principles.

Each of these roles offers unique challenges and rewards, allowing individuals to choose a path that aligns with their skills and interests.

Skills and Qualifications Needed for Welding Jobs

Welding is a skill-intensive profession that requires a blend of technical knowledge, physical ability, and attention to detail. To succeed in this field, individuals must possess a variety of skills and qualifications.

Some essential skills and qualifications include:

- Technical Skills: Proficiency in various welding techniques, such as MIG, TIG, and arc welding, is crucial. Understanding blueprints and engineering drawings is also important.

- Physical Fitness: Welding can be physically demanding, requiring strength, dexterity, and the ability to work in challenging environments.

- Certification: Many employers prefer or require certification from recognized organizations, such as the American Welding Society (AWS).

- Attention to Detail: Precision and accuracy are critical in welding, as mistakes can lead to structural failures or safety hazards.

By developing these skills and obtaining the necessary certifications, aspiring welders can enhance their employability and advance their careers.

Training and Education Opportunities for Welders

For those interested in pursuing a career in welding, there are numerous training and education opportunities available across the United States. These programs provide the foundational skills and knowledge needed to succeed in the industry.

Some popular training options include:

- Community Colleges: Many community colleges offer welding programs that cover the basics and provide hands-on experience. These programs often lead to an associate degree or certificate.

- Trade Schools: Specialized trade schools focus on welding and related skills, offering intensive training programs that prepare students for entry-level positions.

- Apprenticeships: Apprenticeships combine on-the-job training with classroom instruction, allowing individuals to earn while they learn. These programs are often sponsored by employers or unions.

- Online Courses: For those who prefer a flexible learning environment, online courses offer a convenient way to gain welding knowledge and skills.

By exploring these options, aspiring welders can find a program that fits their needs and sets them on the path to a successful career.

Conclusion: The Future of Welding Jobs in the United States

The welding industry in the United States is poised for continued growth, offering numerous opportunities for skilled professionals. As infrastructure projects expand and manufacturing demands increase, the need for qualified welders will remain strong.

For those considering a career in welding, now is an excellent time to explore the various job opportunities and training options available. With the right skills and qualifications, individuals can secure stable, rewarding positions in this essential industry.

As technology advances and new techniques emerge, the welding profession will continue to evolve, providing exciting challenges and opportunities for those willing to embrace change and innovation.